Are you looking for ways to improve the braking performance of your Toyota Tundra? Upgrade your rotors and get more confidence and better control on your vehicle.

In this guide, we’ll show you how to select and install rotors that are right for your Toyota Tundra. Read on to learn more!

If you drive a Toyota Tundra, you know it is an incredibly capable and powerful vehicle. However, such power comes at the cost of significant braking performance as the vehicle is quite heavy. Regardless, with a few simple upgrades, you can improve the overall performance of your Toyota Tundra’s brakes and make it much safer to drive in any situation.

To improve the braking performance of your Toyota Tundra, it’s important to understand all the components involved in its braking system. The brake rotors are the part responsible for slowing down and stopping your vehicle, so it makes sense to start with them in order to get better overall braking performance.

In this guide, we will go over everything you need to know about choosing and replacing rotors for your Toyota Tundra. We’ll talk about different types of rotors available and how they can help improve your vehicle’s braking performance and safety on the road. We’ll then go into detail about how to replace them properly and safely so that you can be sure that your new rotors are up to par in terms of functionality as well as aesthetics.

Explanation of the importance of brake rotors in a vehicle

Brake rotors play a fundamental role in ensuring that your Toyota Tundra has stopping power. Rotors work by converting the energy generated from brake pads pressing against them into thermal energy, allowing the vehicle to slow down and eventually stop. Additionally, brake rotors are designed to dissipate heat away from the brakes in order to maintain a more consistent stopping performance.

The importance of properly working brake rotors cannot be overstated as any failure can potentially cause an accident or lack of control over the vehicle. When selecting a replacement rotor for your Tundra, several factors should be taken into consideration such as material, size and design features that can provide greater braking power and performance. Knowing what to look for when shopping for new rotors and installing them correctly is paramount to ensuring that your vehicle is capable of doing its job right when it comes time to stop.

Brief overview of the Toyota Tundra

The Toyota Tundra is a full-size pickup truck that was first introduced in 1999. It is currently offered in five distinct trim levels and has earned various accolades from the automotive industry for its innovative design and dependability.

When it comes to its braking system, the Tundra utilizes large rotors with durable calipers in order to provide superior stopping power. However, these brakes are subject to wear and tear over time, so upgrading them can help improve the vehicle’s performance and safety.

This guide will provide an overview of how to upgrade the rotors on a Toyota Tundra as well as review some important points to consider before you make any modifications.

Stock Toyota Tundra Brake System

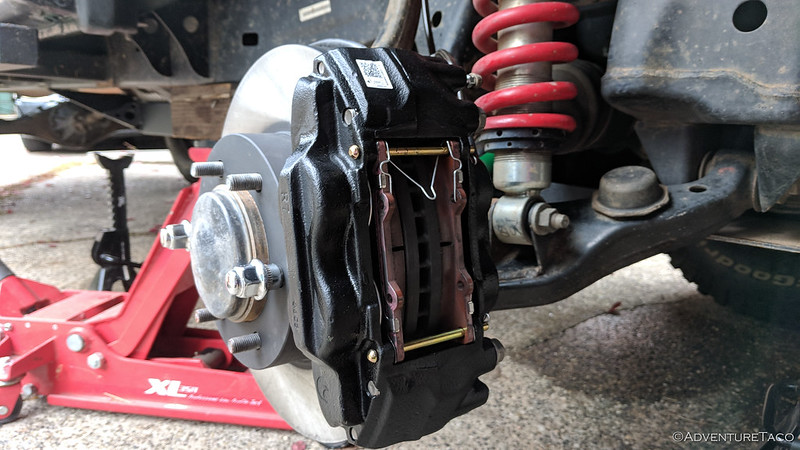

The stock brake system for the Toyota Tundra is made up of a few key components. The brakes are mechanical disc brakes with a cast iron rotor and a pair of steel brake pads per wheel. This type of brake system utilizes friction to stop the vehicle, which means that if the rotors are damaged or worn, the vehicle will not stop as quickly. In order to maximize braking performance, it is important to inspect your rotors for signs of wear and replace as needed. In addition to inspecting the rotors, you should also look at the brake pads, calipers and other components that make up your Tundra’s stock braking system.

The caliper holds the brake pads in place while providing force when pressing on the rotor. The caliper design can differ between various vehicles but generally includes twin pistons with metal cups that house either rubber seals or dust boots. These boots help to keep dirt and debris from entering into your vehicle’s braking system when driving. If these boots become cracked or excessively worn, it can lead to air entering into your braking system due to decreased pressure in the lines leading from individual wheel cylinders which can cause premature wear on other components such as rotors and pads.

*Always remember to follow OEM (Original Equipment Manufacturer) recommended service intervals when servicing your vehicle’s brakes!

Explanation of the stock brake system components

The stock brake system of a Toyota Tundra included a combination of parts that allow the vehicle to come to a stop quickly and safely. The most essential components are the rotors, pads, calipers, and master cylinder. To ensure safe braking performance, it is important to have all of these elements properly functioning.

Rotors: The rotors are responsible for providing the friction necessary to slow or stop wheel rotation when the brakes are applied. They are attached to the wheel and made up of two metal discs with curved surfaces, respectively on their inner and outer diameters. The curvature helps create an attachment point for brake pads and is referred to as a “hat-shaped” rotor design. On most vehicles, these rotors can either be cast iron or an composite material such as aluminium; depending on what type of rotor you have will heavily influence your overall braking performance.

Pads: The pads are metal blocks that press against your brake rotor during operation as part of a friction-based braking system. They are designed in such a way that when pressure is applied by foot pedal against them, they will create resistance against the rotor surface which then causes it to slow down or stop rotation entirely in moments depending on the force used by your foot pedal actuation during application. It is important that you use quality replacement brake pads if you ever need to service or upgrade your brakes – not just any brand will do!

Calipers: Calipers house your vehicle’s brake pad assemblies and act as hydraulic pistons by pressing them onto the brakes discs or rotors in order to make contact with one side while releasing its hold on another in order for them both match each other in speed before being released again after actuation is over. This house also serves another purpose – controlling movement along with modulating temperature through either dissipative friction (heat release) or motional energy conversion via mechanisms like regeneration where electro-magnetic components convert kinetic energy back into electricity so it can be reused later!

Master Cylinder: The master cylinder provides pressurized fluid from its reservoir tank into any number of caliper cylinders depending on how many individual wheel sets exist within an entire vehicle setup at once (i.e., four-wheel drives). When input pressure is detected through movement of master cylinders piston arm coming from foot pedal actuation along with other corresponding architecture components exist inside its housing – i,.e., motors/sensors etc.- then this tells entire braking system which wheels require more/less pressure so all four remain balanced throughout operation which ultimately results in smooth dynamic wheel movements even under tough driving conditions like off roading etc.

Limitations of the stock brake rotors for the Toyota Tundra

The stock brake rotors that come with the Toyota Tundra are designed to provide an adequate braking performance for daily usage. However, in certain situations, those factory rotors may not be able to meet the demands that more aggressive driving can put on them. If you are looking to upgrade your braking performance, then there are a few things to consider before selecting brake rotors.

One of the primary limitations of stock Toyota Tundra brake rotors is their material composition. Oftentimes, stock rotors are made from a softer grade of steel and may not be able to handle increased heat without warping or cracking. Additionally, many stock brakes feature venting designs with narrow slots that don’t allow for sufficient cooling during frequent aggressive stops and starts, resulting in fading brake performance over time.

Stock brake rotors are also limited by their size as they may simply not be large enough in diameter or thick enough in width to provide the necessary torque output required for more demanding braking scenarios encountered during racing or heavy-duty off-road use. Thicker and larger rotor dimensions improve torque output while allowing additional mass which increases cooling capacity and improves heat dispersion away from the friction surface.

Finally, many aftermarket brake rotor kits include directional finishes aimed at expending water away from the contact surface during rain and wet weather conditions for improved grip on slick surfaces where stopping distances can make all the difference between success and disaster.

III. Factors to Consider When Upgrading Toyota Tundra Brake Rotors

When upgrading your Toyota Tundra brake rotors, there are several factors to bear in mind. The original manufacturers may have used a certain number of vane or rib design, as well as different metal alloys that were chosen to suit the needs of the model and its conditions. Depending on where you plan to use the upgraded rotor and what kind of braking performance you want, these factors can make a significant difference in how you choose your new rotors.

Vane Design – The design of the vane determines the shape of the cooling channels circulating air from the hub center. The more intricate a rotor’s design is, the greater number of vanes will be able to fit within it – resulting in a rotor with more effective thermal dynamics that can dissipate heat more quickly.

Metal Alloy – In general, high carbon content alloys provide increased strength and wear resistance, capable of withstanding higher operating temperatures than conventional materials. Low carbon alloys boast greater ductility and impact strength than other metals but can corrode easily due to their inability to hold a surface finish for very long periods.

Directional or Non-directional – Directional rotors feature pads engineered specifically for them, usually under two different pad friction values depending on whether they are used on either left or right wheels. Non-directional brake rotors may lack directional capability but typically offer improved safety levels at lower operational temperatures compared to directional types.

Materials used in brake rotor construction

To understand better how to improve your Toyota Tundra’s braking performance, it’s important to understand the different materials used in brake rotor construction. After all, brake rotors are responsible for providing the friction necessary to bring a vehicle to a stop and upgrading them can substantially boost your braking capability.

The two most common materials that brake rotors are made from are cast iron and ceramic. Cast iron has long been the preferred choice due to its cost-effectiveness, but recently ceramic material has become more popular due to its higher performance and longer life expectancy.

Cast Iron Brake Rotors

Cast iron is the most widely used material for brake rotors because it provides reliable stopping power at an affordable price point. As its name suggests, cast iron rotors are created by pouring molten iron into a mold, so they tend to be extremely heavy and strong. This strength allows them to withstand extreme temperatures during hard braking without warping or cracking. On the downside, since nearly all of their mass is concentrated in their outer edge they don’t dissipate heat as quickly as some other materials might which can cause premature wear and damage over time.

Ceramic Brake Rotors

Unlike cast iron rotors which have virtually all of their mass concentrated around the outer edge, ceramic brakes have their mass evenly distributed throughout the entire surface area making them lighter than traditional cast iron brakes—as much as 40% lighter in some cases—while still offering superior stopping power. Additionally, this even distribution means they dissipate heat faster allowing them to last longer under hard braking conditions than traditional brakes (e.g., during off-road use). The downside is that ceramic rotors tend to be significantly more expensive than traditional brakes which may make them prohibitively expensive for some drivers.

Design features that affect brake performance

When selecting Toyota Tundra rotors for your truck, there are several design features that can affect the performance of the braking system. The disc size should match that of the original equipment to ensure compatibility and your brakes are able to handle a greater demand. The material used in rotor construction also plays an important role, as higher-grade materials may have better heat dissipation qualities or increased longevity. It is also important to consider special features such as dimpled or drilled holes. These constructions are designed to reduce weight without sacrificing strength and stiffness.

In addition to the features of the individual part, attention should also be paid to how it is mounted onto the vehicle itself. Check for proper clearance between the rotor and caliper parts in order to ensure maximum performance from your brake system. Improperly mounted parts can make for shorter lifespan and less responsive braking.

With careful setup and selection of components, you can increase safety, longevity, reliability and overall performance from your Toyota Tundra’s brakes with upgraded rotors.

Conclusion

Conclusively, upgrading your Toyota Tundra brake rotors for better braking performance is a great way to ensure that your truck performs optimally in a variety of driving conditions. Investing in high quality, durable brake rotors and pads will not only provide you with reliable performance but also increase your vehicle’s longevity and safety.

Talk to an experienced professional to determine the best fit for your specific needs, budget, and driving style. With proper installation and regular care, upgraded braking components will help keep you on the road longer for more enjoyable travels.

FAQ’s

How can I improve my braking performance?

By upgrading your brake pads, rotors, and calipers, ensuring proper tire pressure, and maintaining your braking system regularly.

Can you upgrade brake rotors?

Yes, you can upgrade brake rotors to improve braking performance.

Is it worth upgrading brake rotors?

It depends on your driving needs and preferences. Upgrading brake rotors can improve braking performance, but it may not be necessary for everyone.

Does Toyota recommend turning rotors?

Toyota recommends replacing rotors instead of turning them, as turning can reduce their thickness and compromise their performance.

Are thicker brake rotors better?

Thicker brake rotors can dissipate heat better and provide better braking performance, but they may also be heavier and more expensive.

What is the benefit of a larger rotor?

A larger rotor can provide better heat dissipation and improved braking performance, especially in high-performance vehicles.

Can you increase braking power?

Yes, you can increase braking power by upgrading your brake system components, such as brake pads, rotors, and calipers.

What are the 3 main factors for braking performance?

The three main factors for braking performance are the friction between the brake pads and rotors, the force applied by the calipers, and the heat dissipation of the braking system.

How can I improve my truck brakes?

You can improve your truck brakes by upgrading your brake system components, ensuring proper tire pressure, and maintaining your braking system regularly.

How long do Toyota Tundra rotors last?

The lifespan of Toyota Tundra rotors can vary depending on driving conditions and maintenance, but they typically last between 30,000 and 70,000 miles.

See Also-

- Best tuner for toyota tundra

- Best 275 60r20 tires for toyota tundra

- Best performance chip for toyota tundra

- Best air bags for toyota tundra

- Best rotors for toyota tundra